CNC Turned Components Supplier: Precision in Industry

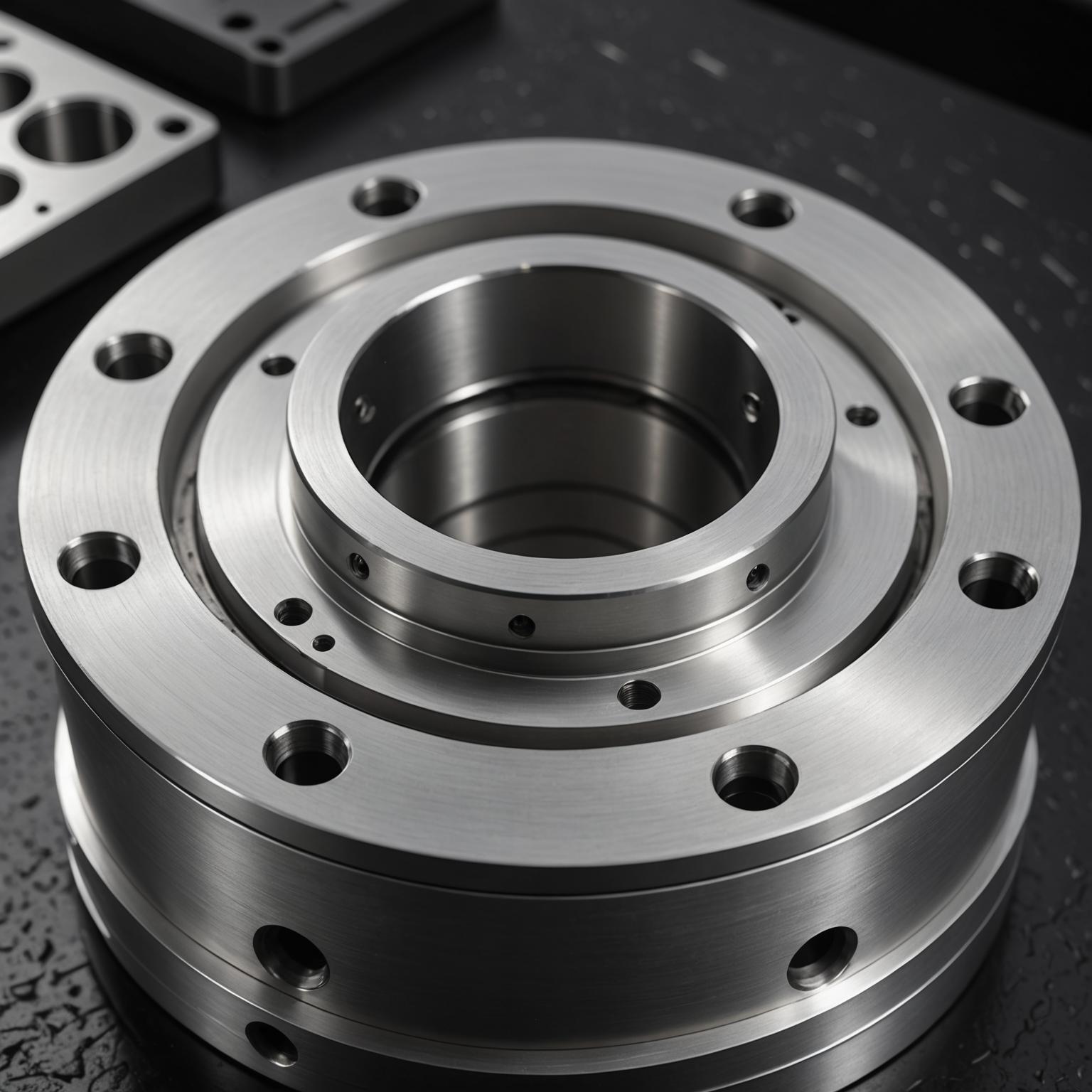

Modern manufacturing depends on precision. From automotive shafts to aerospace fittings, CNC turned components are the hidden backbone behind mechanical reliability. As a professional CNC turned components supplier, Liqin combines high-precision equipment, strict inspection systems, and global production experience to deliver components that meet the most demanding industrial standards.

Understanding CNC Turning in Modern Production

CNC turning is a process that shapes cylindrical materials using automated lathes controlled by digital commands. It is particularly suited for producing symmetrical parts with high dimensional accuracy.

Key Features of CNC Turning:

-

High Consistency: Automated operation ensures every unit meets identical specifications.

-

Fast Cycle Time: Ideal for large-volume production without compromising quality.

-

Material Flexibility: Works with stainless steel, aluminum, brass, and engineering plastics.

-

Superior Surface Finish: Smooth, burr-free surfaces reduce post-processing needs.

These characteristics make turning one of the most efficient methods for precision shaft components, threaded parts, and mechanical connectors used in industrial assemblies.

How Turning Precision Drives Industrial Reliability

Every rotation matters when accuracy defines performance. Liqin’s advanced CNC turning centers are designed to maintain micron-level tolerances while optimizing productivity.

Core Technical Advantages:

-

Multi-Spindle CNC Lathes: Handle multiple components simultaneously for higher throughput.

-

Real-Time Axis Feedback: Adjusts automatically to maintain accuracy even under tool wear.

-

Integrated Thread Cutting & Boring: Supports internal/external threading and complex shapes.

-

Temperature-Stabilized Machining: Prevents expansion-induced deviations during continuous runs.

-

Full Digital Traceability: Every batch linked to machine parameters and operator logs.

This approach ensures every turned component—from miniature pins to heavy-duty shafts—meets performance expectations in automotive, robotics, and industrial machinery applications.

Materials and Finishes for CNC Turned Parts

Selecting the right material and finish ensures the part’s longevity and functionality in its working environment.

| Material | Typical Application | Surface Finishing Options |

|---|---|---|

| Stainless Steel 303 / 316 | Automotive, marine | Polishing, passivation |

| Aluminum 6061 / 7075 | Aerospace, electronics | Anodizing, powder coating |

| Brass & Copper | Electrical, decorative parts | Plating, brushing |

| Carbon Steel | Industrial shafts, tools | Black oxide, hard coating |

| Engineering Plastics | Lightweight parts | Machined finish |

Each selection is guided by mechanical requirements—strength, corrosion resistance, and assembly compatibility—ensuring durability and precision across industries.

Quality Control: Where Accuracy Meets Verification

Precision turning relies on metrology and quality management. Every process stage is monitored to ensure dimensional and visual compliance with client specifications.

Inspection Capabilities Include:

-

Coordinate Measuring Machines (CMM)

-

Digital Calipers & Micrometers

-

Surface Roughness & Concentricity Tests

-

Thread Gauge Verification

-

Hardness and Composition Analysis

Quality Targets:

| Indicator | Goal |

|---|---|

| Tolerance Accuracy | ±0.005 mm |

| Outgoing Pass Rate | ≥ 99% |

| Measurement Repeatability | ≤ 0.002 mm variance |

| Client Satisfaction Rate | ≥ 98% |

Each order is accompanied by full inspection documentation, allowing OEM clients to trace quality back to the production line.

Applications of CNC Turned Components

Turned components are used across diverse industries, from everyday machines to specialized systems that demand long-term precision.

Industrial Applications Include:

-

Automotive: Shafts, couplings, and transmission pins.

-

Aerospace: Hydraulic fittings and fuel system connectors.

-

Electronics: Threaded studs, adaptors, and spacers.

-

Medical Devices: Surgical tool handles and assembly pins.

-

Energy Equipment: High-pressure connectors and sealing rings.

Their high dimensional stability ensures that every part operates reliably in dynamic, high-stress environments.

FAQs: What Buyers Want to Know

Q1: What is the maximum diameter for CNC turned parts?

Depending on the lathe type, components up to 350 mm in diameter can be machined.

Q2: Does the supplier provide prototype samples?

Yes, prototypes are available for design verification before bulk production.

Q3: Are materials traceable?

All materials come with batch certificates and supplier traceability records.

Q4: Can surface treatment be customized?

Yes, multiple finishing options such as anodizing, plating, or black oxide are available.

Q5: How does the supplier ensure consistency in mass production?

Automated measurement feedback systems and regular calibration maintain dimensional accuracy throughout large-scale runs.

Building Precision Partnerships for the Future

In today’s supply chain, consistency and dependability matter as much as price and delivery. Through engineering control, precision inspection, and process innovation, Liqin stands as a trusted CNC turned components supplier serving industries worldwide.

To explore technical capabilities or request a quotation, visit the Homepage or contact the engineering team directly via the Contact Us page.