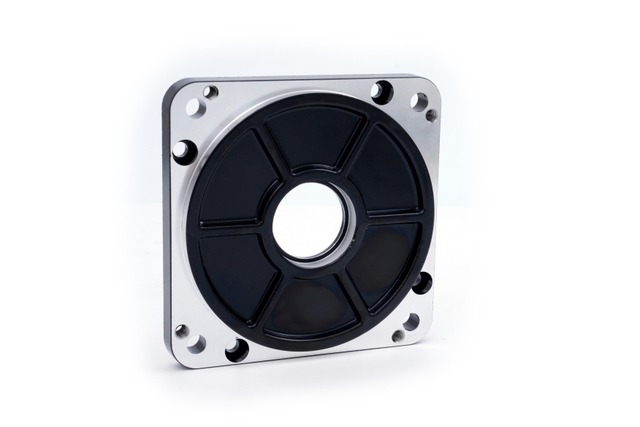

Product Description

| thing | describe |

| Design/Size | According to customer's drawings or samples |

| Material |

Aluminum: 6061, 6063, 6082, 7075, 5052, A380, etc. Stainless steel: SS201, SS301, SS303, SS304, (SS304 food grade), SS316, SS316L, SUS430, SS416 Steel: low carbon steel, carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. Alloy steel (15Cr, 20Cr, 42CrMo), etc. Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, etc. Copper, bronze, copper, etc. Titanium: TC4 (TiAl6v4, Grade f5) Plastic: ABS, PC, PE, POM, Delrin, Nylon, Plastic, PP, PEI, Peek, etc. |

| process | CNC machining, turning, milling, stamping, turning, cutting, etc. |

| Delivery time | Samples usually take 3-7 working days, and mass production will be carried out according to the detailed quantity after sample approval. |

| Surface treatment | Transparent anodizing, color anodizing, chemical coating, brushing, passivation, polishing, chrome plating, sandblasting, laser engraving, zinc plating, black oxide, nickel plating, chrome plating, carburizing, heat treatment, painting |

| Test equipment | Coordinate measuring machine (CMM), 2D measuring instrument, projector, altimeter, micrometer, thread gauge, hardness tester, caliper, pin gauge, salt spray tester, concentricity measuring instrument, spectrometer. |

| Quality Management System |

ISO 9001:2015 ISO 13485:2016 |

| application | Auto parts, machinery parts, computer parts, medical parts, home appliance parts, electrical parts, electronic product parts, electronic parts, generator parts, alternator parts, generator parts, stationery, power switches, micro switches, construction, merchandise and A/V equipment. |

| File Format | Solidworks, Pro/Engineer, CAD, PDF, JPG, DXF, IGS |

| Package | Inner plastic bag, outer standard carton, or as per customer's requirements |

| Shipping | Sea freight, air freight, international express (DHL, FedEx, TNT, UPS). |

| Serve | The professional foreign trade team provides enthusiastic and fast response services. Dimensional inspection report/Raw material certificate/Surface treatment report/Engineering drawing RoHS report/Salt spray test report/Hardness test report |