CNC Aluminum Machining Service: Lightweight Precision for Modern Manufacturing

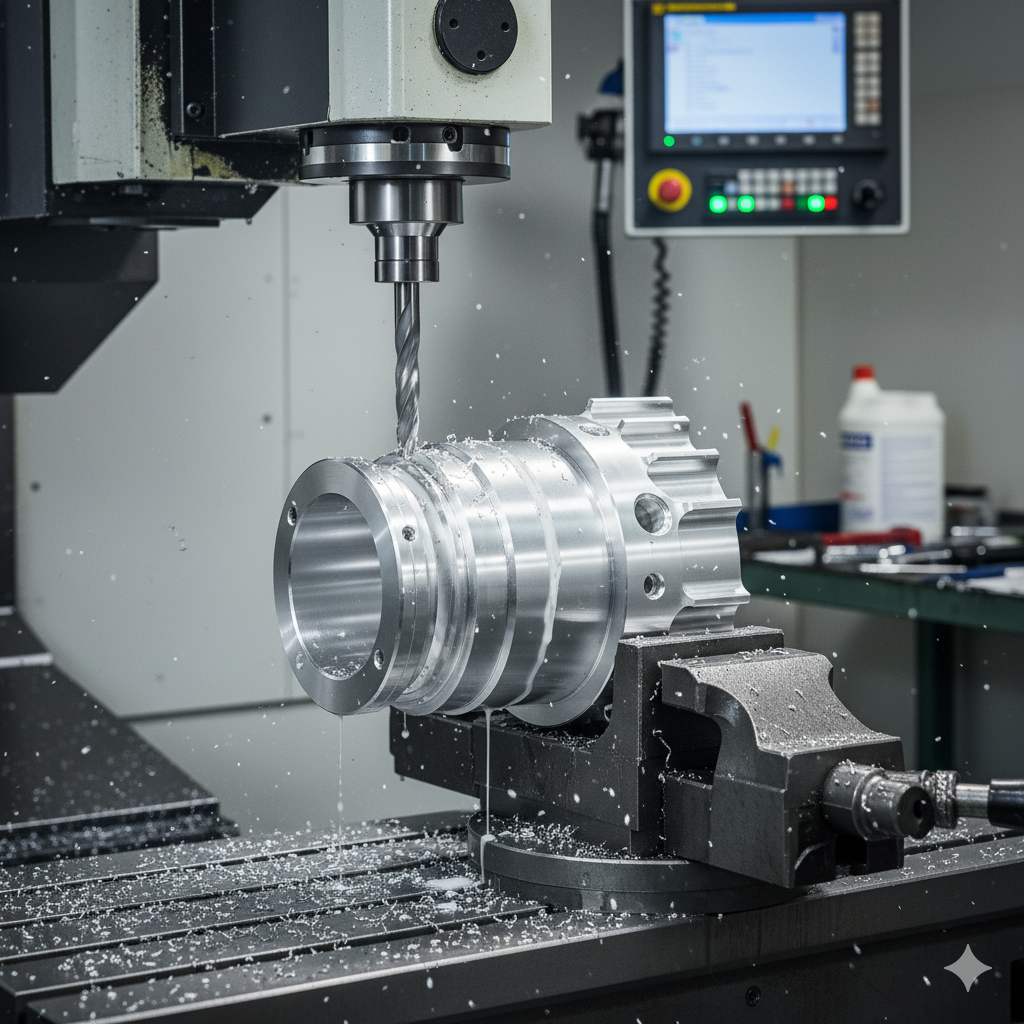

In an era where every gram and millimeter matters, CNC aluminum machining service stands out for its balance of precision, performance, and efficiency. Aluminum’s combination of low density, high strength, and excellent thermal properties makes it the preferred material for industries seeking both lightness and durability. Through advanced milling, turning, and surface treatment systems, Liqin delivers aluminum components that meet the evolving needs of aerospace, automotive, electronics, and industrial manufacturing.

Why Aluminum Is the Ideal Machining Material

Aluminum’s physical and chemical properties make it one of the most versatile metals for precision machining. It’s strong yet lightweight, corrosion-resistant, and easy to finish, making it ideal for high-performance parts in compact spaces.

Core Advantages of Aluminum Machining:

-

Lightweight Strength: Reduces overall assembly weight without sacrificing rigidity.

-

Excellent Machinability: Allows faster cutting speeds and complex geometries.

-

Thermal Conductivity: Ideal for heat sinks and electronic housings.

-

Surface Finish Flexibility: Compatible with anodizing, polishing, or coating.

-

Recyclability: Eco-friendly and cost-efficient for sustainable manufacturing.

These advantages explain why aluminum is a top choice for industries demanding efficiency, precision, and scalability.

Inside the Aluminum CNC Machining Process

Aluminum machining requires the right combination of speed, tooling, and precision control. Liqin’s CNC systems optimize cutting dynamics to prevent tool chatter and maintain dimensional stability.

Aluminum Machining Workflow:

-

Material Selection & Analysis – Matching alloy grades (6061, 7075, 2024) to mechanical needs.

-

High-Speed Milling & Turning – Achieving ±0.005 mm accuracy even in thin-walled parts.

-

Coolant & Chip Control Systems – Maintain temperature and prevent deformation.

-

Surface Treatment Integration – Anodizing, sandblasting, or powder coating for appearance and protection.

-

Full Inspection & Documentation – Ensuring quality consistency across batches.

By combining multi-axis machining and real-time feedback systems, Liqin ensures stable performance even for lightweight structural parts.

Material Grades and Their Applications

Different aluminum alloys serve unique industrial purposes.

| Alloy | Key Features | Typical Application |

|---|---|---|

| Aluminum 6061 | General purpose, strong, corrosion-resistant | Brackets, frames, housings |

| Aluminum 7075 | High strength-to-weight ratio | Aerospace, automotive parts |

| Aluminum 2024 | Excellent fatigue resistance | Mechanical connectors, gears |

| Aluminum 5052 | Easy to form, weld, and polish | Panels, covers, and casings |

| Aluminum 6082 | High load-bearing strength | Machine components and fixtures |

Selecting the right grade helps balance mechanical properties, cost, and aesthetic requirements for each project.

Surface Finishing: Function Meets Aesthetics

The finishing stage is crucial for both performance and appearance. Liqin integrates a full suite of in-house finishing solutions.

Available Finishes:

-

Anodizing: Corrosion resistance and color options.

-

Bead Blasting: Matte texture for improved aesthetics.

-

Polishing: Mirror-like finish for decorative or precision optical parts.

-

Powder Coating: Added protection for harsh environments.

-

Electroplating: Enhanced conductivity and wear resistance.

This range allows clients to achieve both functional and branding objectives in a single production flow.

Quality, Efficiency, and Repeatability

CNC aluminum machining requires balancing lightness with dimensional consistency. Liqin’s quality system ensures repeatable excellence through process control and advanced inspection tools.

Inspection Highlights:

-

Coordinate Measuring Machine (CMM) verification

-

Surface roughness and hardness testing

-

Optical contour and flatness measurement

-

Material certification and traceability

Quality Benchmarks:

| Parameter | Standard |

|---|---|

| Dimensional Accuracy | ±0.005 mm |

| Surface Roughness (Ra) | ≤ 0.8 μm |

| Outgoing Pass Rate | ≥ 99.5% |

| Complaint Response Time | < 24 hours |

Such discipline ensures every component meets not only engineering specifications but also visual perfection.

FAQs: About CNC Aluminum Machining

Q1: What industries benefit most from CNC aluminum machining?

Aerospace, automotive, electronics, robotics, and energy equipment manufacturing rely heavily on aluminum parts.

Q2: Can aluminum parts be both lightweight and durable?

Yes. Alloys like 7075 provide aircraft-grade strength at a fraction of the weight of steel.

Q3: What is the typical lead time for production?

Prototypes can be delivered within 5–7 days, while full production runs take 10–20 working days.

Q4: Can surface finishing be customized?

Yes. Clients can choose color, texture, and coating type according to function or branding needs.

Q5: Does Liqin handle export packaging?

Yes. Each shipment includes protective packaging, inspection certificates, and export documentation.

Precision That Transforms Design into Reality

Lightweight doesn’t mean fragile—when precision meets engineering, aluminum components deliver unmatched performance and design freedom. Through a combination of high-speed machining, alloy expertise, and integrated finishing, Liqin helps global manufacturers create durable, efficient, and aesthetically refined products.

By working with an experienced machining partner, clients gain more than a supplier—they gain a team that understands industrial challenges, supports technical decisions, and delivers consistent quality worldwide.

To discuss your next aluminum machining project or request a detailed quotation, visit the Homepage or contact the Liqin team directly via the Contact Us page.