Product Description

| thing | describe |

| Design/Size | According to customer's drawings or samples |

| Material |

Aluminum: 6061, 6063, 6082, 7075, 5052, A380, etc. Stainless steel: SS201, SS301, SS303, SS304, (SS304 food grade), SS316, SS316L, SUS430, SS416 Steel: low carbon steel, carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. Alloy steel (15Cr, 20Cr, 42CrMo), etc. Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, etc. Copper, bronze, copper, etc. Titanium: TC4 (TiAl6v4, Grade f5) Plastic: ABS, PC, PE, POM, Delrin, Nylon, Plastic, PP, PEI, Peek, etc. |

| process | CNC machining, turning, milling, stamping, turning, cutting, etc. |

| Delivery time | Samples usually take 3-7 working days, and mass production will be carried out according to the detailed quantity after sample approval. |

| Surface treatment | Transparent anodizing, color anodizing, chemical coating, brushing, passivation, polishing, chrome plating, sandblasting, laser engraving, zinc plating, black oxide, nickel plating, chrome plating, carburizing, heat treatment, painting |

| Test equipment | Coordinate measuring machine (CMM), 2D measuring instrument, projector, altimeter, micrometer, thread gauge, hardness tester, caliper, pin gauge, salt spray tester, concentricity measuring instrument, spectrometer. |

| Quality Management System |

ISO 9001:2015 ISO 13485:2016 |

| application | Auto parts, machinery parts, computer parts, medical parts, home appliance parts, electrical parts, electronic product parts, electronic parts, generator parts, alternator parts, generator parts, stationery, power switches, micro switches, construction, merchandise and A/V equipment. |

| File Format | Solidworks, Pro/Engineer, CAD, PDF, JPG, DXF, IGS |

| Package | Inner plastic bag, outer standard carton, or as per customer's requirements |

| Shipping | Sea freight, air freight, international express (DHL, FedEx, TNT, UPS). |

| Serve | The professional foreign trade team provides enthusiastic and fast response services. Dimensional inspection report/Raw material certificate/Surface treatment report/Engineering drawing RoHS report/Salt spray test report/Hardness test report |

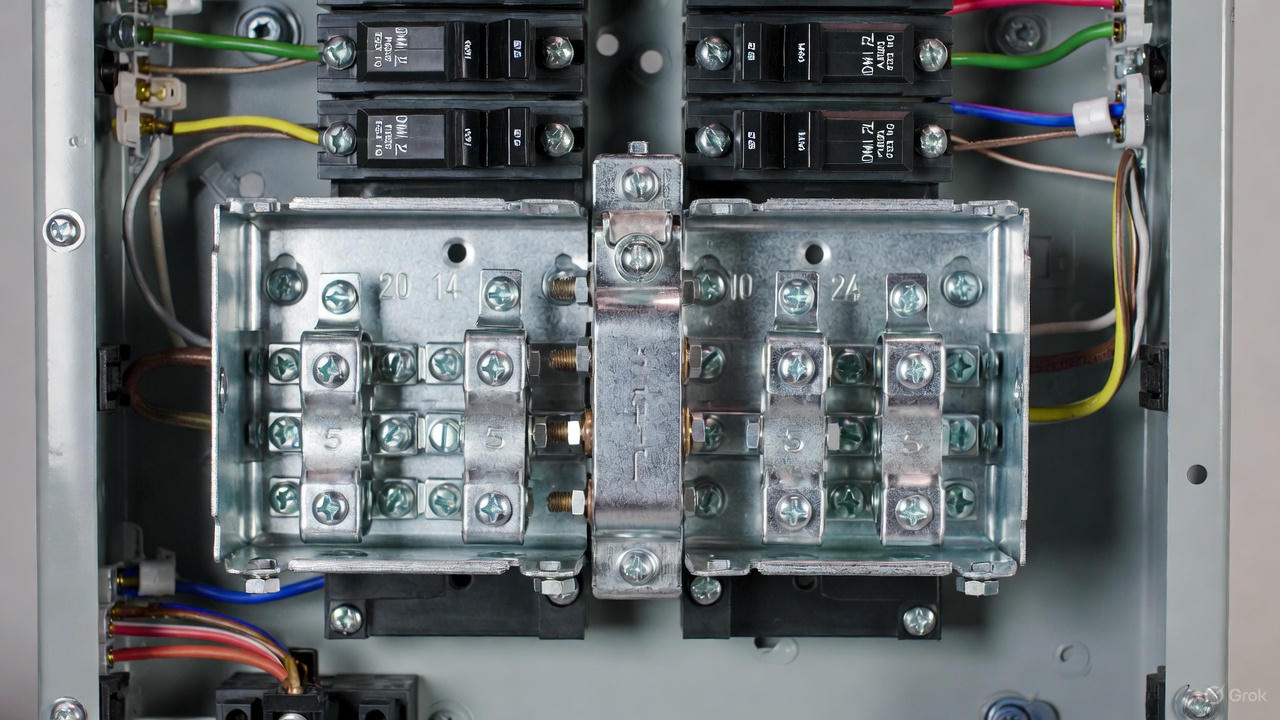

1. Product Overview: High-Performance Power Connection

This component serves as a critical link in electrical distribution systems. It is engineered not just for securing wires, but for ensuring stable, low-resistance power transmission.

Advanced Material Selection: The part is machined from Aluminum 6061-T6. This alloy provides an optimal balance of high mechanical strength and excellent thermal conductivity, which is essential for dissipating heat during high-current operations.

Surface Protection & Conductivity: The entire component is Tin Plated. This finish prevents the formation of high-resistance oxide films on the aluminum surface and protects against galvanic corrosion when connected to various conductor types.

Integrated Assembly: The design features 15 sets of 7/16-20 UNF threads. We supply the component with all 15 set screws (Oval Point) pre-installed to streamline your final assembly process.

2. Precision Manufacturing Process

To maintain the integrity of the triple-step geometry and the precision of the numerous threaded ports, we utilize the following workflow:

Multi-Axis CNC Milling: Using high-precision CNC centers, we machine the triple-step profile and all mounting holes in a single setup. This ensures that the geometry perfectly matches the provided 700-0221.SLDPRT solid model.

Bottom Tap Threading: Per the specification, we perform Bottom Tap Full Depth threading for the 7/16-20 UNF holes. This provides maximum thread engagement even in blind-hole conditions.

Surface Finishing: We implement a rigorous deburring and polishing process to ensure all surfaces are consistent, smooth, and free of scratches, nicks, or blemishes.

3. Technical Challenges & Solutions

A. Maintaining High Process Capability (Cpk)

The Challenge: The drawing requires a process capability (Cpk) greater than 1.33.

Our Solution: We employ Statistical Process Control (SPC) for all dimensions, particularly those marked as Critical Dimensions (in ovals). By monitoring real-time data, we adjust for tool wear before any part falls out of the required range.

B. Geometry and Model Alignment

The Challenge: The component's geometry must strictly match the supplied solid model.

Our Solution: Our engineering team uses the native CAD file for CAM programming and CMM (Coordinate Measuring Machine) verification, ensuring 100% fidelity between the physical part and the digital design.

C. Thread Integrity & Screw Installation

The Challenge: Installing 15 set screws into fine-pitch threads requires perfect thread alignment and cleanliness.

Our Solution: Each thread is cleaned and inspected with a go/no-go gauge prior to the installation of the oval-point set screws. This guarantees that the screws turn smoothly and provide reliable clamping force in the field.

4. Quality Assurance & Delivery

Clean Packaging: Parts are packaged in clean, protective containers to prevent damage during shipment or storage.

Full Traceability: We provide material certifications and inspection reports to confirm that all technical requirements of Rev A have been met.

https://www.instagram.com/liqincnc/

https://wa.me/8618757148656

https://x.com/LZhou57936

https://www.tiktok.com/@zhouli980206