Quality Philosophy

At Liqin, we firmly believe that "Excellence is the benchmark for quality, not just being acceptable." We go beyond meeting industry standards by exceeding every expectation through advanced precision metal processes. With a dedication to continuous improvement and stringent quality control—supported by ISO9001:2015 and IATF16949:2016 certifications—we aim to deliver refined, tailored solutions to our global clients.

Our Quality Team

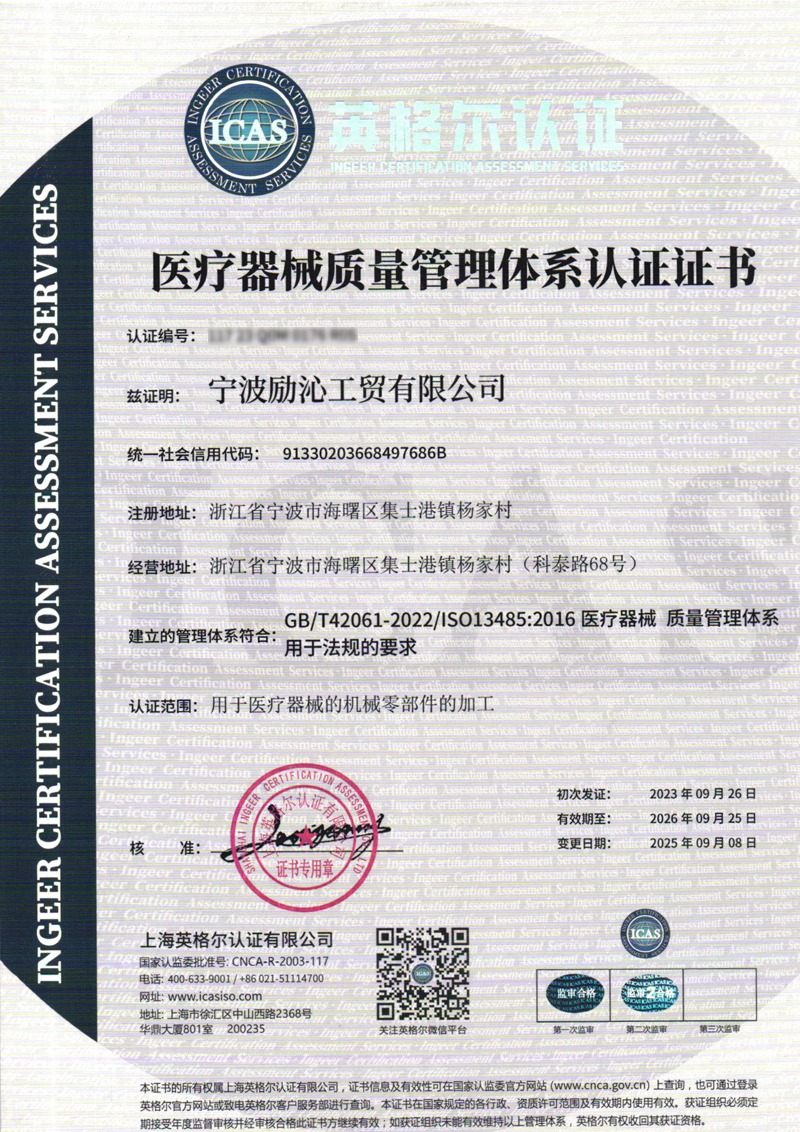

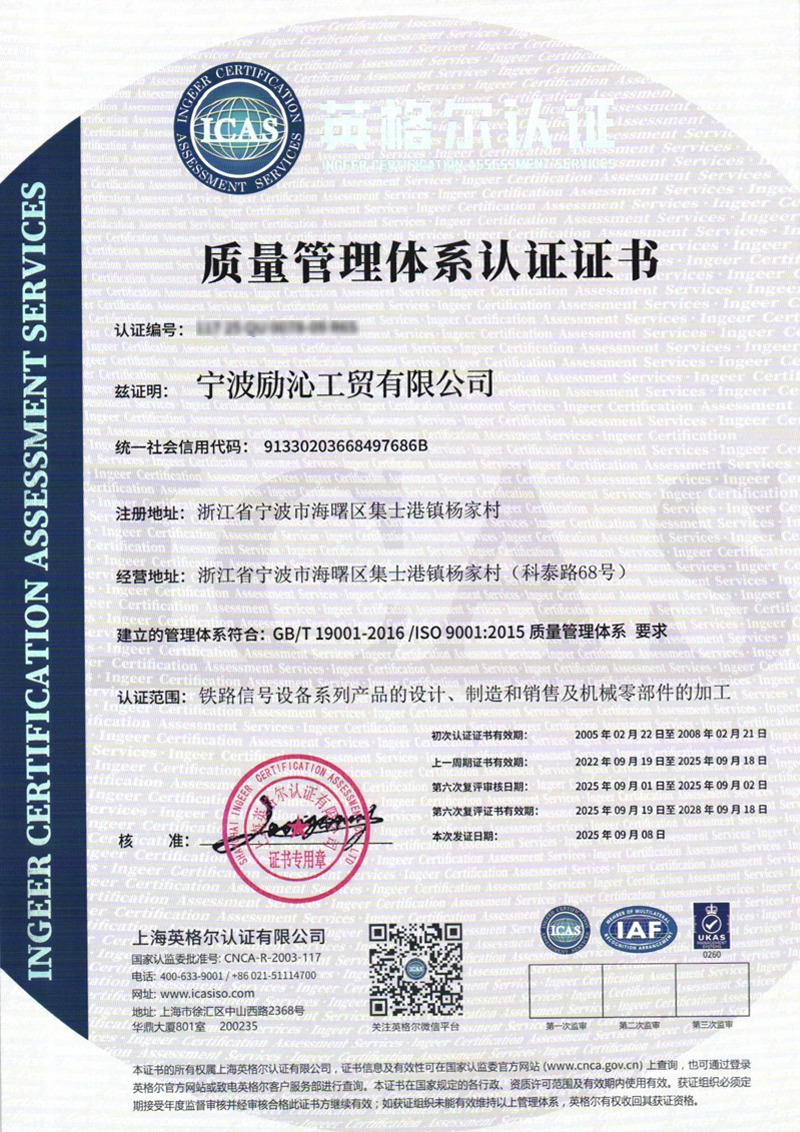

International Certifications

LS and its brother factories and partners have acquired various international quality certificates,including iS0 9001,1S0 13485, 1S0 14001, and iS045001, ensuring our products and services meet global quality standards. We understand that quality system certifications are just the foundation. To achieve excellence, we must focus on every detail to deliver products that exceed customer expectations

Corporate Culture

Liqin Spirit

Honesty, Hard Working, Responsibility

Liqin Philosophy

People Oriented, Produce Boutique

Quality Policy

Excellent Products, Standard Quality, Advanced Technology, Strict Operation

Quality Objective

- Outgoing Qualified Rate 99%

- Quick Response Rate to Complaint 100%

- Acceptance Rate of One-time Examination 97%

We are committed to customer satisfaction, continuous improvement of quality systems, and quick response to feedback.

Advanced Equipment

We have equipped ourselves with a large number of globally renowned processing and testing equipment to ensure the precision and quality of each metal component. Our main equipment includes:

- Three-Coordinate Measuring Machine (CMM)

- Optical Projector

- Handheld Spectrometer

- Height Gauge

- Surface Profilometer

- Metallographic Microscope

- Surface Roughness Tester

Three-Coordinate Measuring Machine (CMM)

Ensures precise dimensional accuracy for complex metal parts. Used to verify tolerances in CNC-machined components.

Optical Projector

Provides detailed visual inspection of part dimensions and profiles. Ideal for checking surface finishes on die-cast products.

Handheld Spectrometer

Analyzes material composition for quality assurance. Helps identify alloy properties in forged parts.

Height Gauge

Measures vertical dimensions with high precision. Essential for inspecting stack-up heights in assemblies.

Surface Profilometer

Evaluates surface texture and roughness accurately. Critical for assessing post-treatment finishes like anodizing.

Metallographic Microscope

Examines microstructure for material integrity. Used to detect internal defects in metal samples.

Surface Roughness Tester

Assesses surface smoothness to meet client specifications. Ensures compliance with aerospace and automotive standards.

Customer Testimonials

Learn why leading industries rely on Liqin for innovative metal manufacturing. Explore real feedback from our clients, highlighting our expertise in precision engineering, robust quality systems, and dedicated service. Their stories underscore our promise of superior craftsmanship.

Latest News

Stay updated with the latest news and announcements from Liqin Manufacturing. Explore our latest articles below.